An atomic force microscope (AFM) is a very sensitive instrument, often mounted in the lab on a special table which dampens vibrations. Now think of a rocket launch – about as far from “vibration free” as you can get! So designing an AFM for space was a challenge. It has to be capable of surviving the rough ride into orbit, and yet still make precision movements and measurements. In this post I’ll talk a bit about some of the measures taken in the design of MIDAS, the AFM on-board the Rosetta spacecraft, to address this issue.

Moving parts

Although space engineers typically try to avoid mechanisms and moving parts, sometimes they’re necessary. And the very nature of an AFM, which moves a sharp tip over the surface of a sample, means that we cannot avoid moving parts!

We have a coarse approach stage which moves the microscope into contact with the sample.

We have a wheel which rotates to move the sample from its exposure position, facing out to space, to its scanning position. And the wheel can also be moved sideways in front of one of the sixteen cantilevers.

Then there is a shutter which opens and closes to control when dust is allowed into the instrument, and a “one off” cover which protected the instrument from contamination before and during launch.

Finally the actual scanning mechanism, our XYZ stage, has to move in three dimensions.

All of these mechanisms had to be designed to move on demand, and to still work after ten years in space, but at the same time survive the launch. To manage this the engineers designing MIDAS used pretty much every trick in the book, from shape memory alloys and paraffin actuators to pyrotechnic bolts and good old friction.

To give you an idea, here is a list of the key mechanisms and actuators on MIDAS, what they are for, and how they work..

Dust cover

- Purpose: protect the instrument prior to and during launch

- Mechanism: redundant pyrotechnic pins

- How it works: after the holding pins are released, a pre-loaded spring opens the cover

Vibration damping lock

- Purpose: MIDAS is mounted on a vibration damping system, which was clamped for launch, and had to be released

- Mechanism: paraffin actuator (one per pair of clamps)

- How it works: a heater warms a small amount of paraffin wax, which thermally expands and drives a mechanism, in this case releasing the clamps.

XY table launch lock

- Purpose: the heart of the microscope is an XYZ stage, also clamped to avoid damage during launch. Two clamps had to be released after launch

- Mechanism: shape memory alloy

- How it works: the shape memory is warmed by heaters, deforms, and in doing so breaks a locking pin

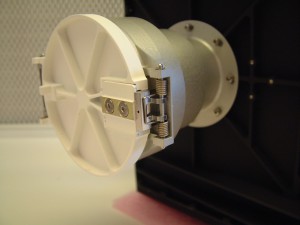

Approach stage

- Purpose: to move the entire microscope into contact with the sample

- Mechanism: DC motor + planetary gearbox

- How it works: just like a motor on Earth! In this case the whole mechanism is encapsulated in a pressure vessel. The motor turns a spindle and drives a wheel between two wedges, moving the microscope to the left in the image

The coarse approach mechanism used to move the MIDAS AFM into contact with the sample

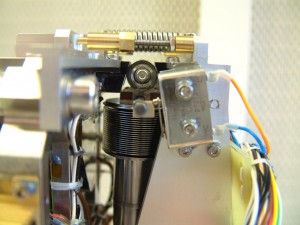

Linear stage, wheel and shutter

- Purpose: the linear stage moves the wheel between the cantilevers and provides coarse “X” positioning

- Purpose: the wheel rotates to move samples from the expose to scan positions, and provides coarse “Y” positioning

- Shutter: the shutter opens and closes to control exposure times

- Mechanism: all three of these mechanisms are driven by commercial pizeo-electric motors, refitted for space use.

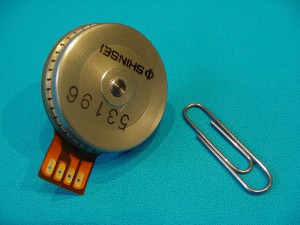

XYZ stage

- Purpose: the heart of the microscope is the XYZ stage which moves the cantilevers up to 100 µm in X and Y and 10 µm in Z

- Mechanism: mechanically amplified piezo actuators

- How it works: applying an electric field to a piezo-electric material causes it to expand – slightly! With mechanical amplification this can be used to make very precise movements.

Hopefully that gives you some idea of the immense thought and care that has to be taken to take an instrument that works on the Earth and make it survive launch, 10 years of flight, and be ready to unlock the secrets of the Solar System… watch this space! 🙂